Tube Laser Cutting Systems Kolkata

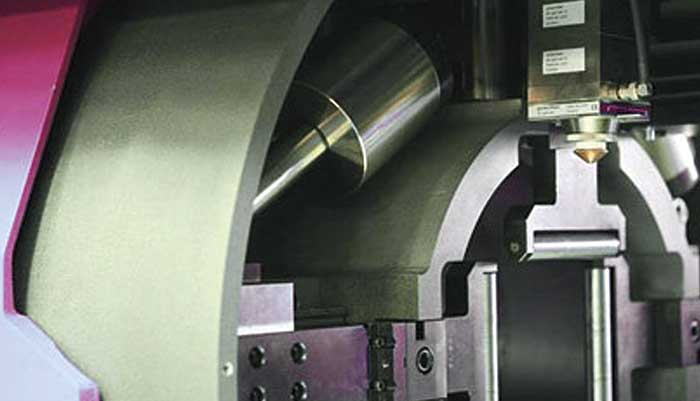

The laser cutting system StarCut Tube SL provides highest accuracy, superior reliability, and high performance when cutting complex medical devices such as stents, aortic valve replacements, or hypotubes.

A laser tube cutting machine doesn't come with any standard material towers. Bundle loading is the best option for handling tube material. It feeds one tube at a given time from the bundle into a tube laser using a singularizing process. This type cannot be used with open profiles (e.g. channels and angles), because they interlock inside the bundles and don’t move freely. Step loaders, which are used for open profile profiles, sequence one section at time into the machine while maintaining the correct orientation.